Footwear is a basic necessity of life and depending on where you are, it’s type and design also changes. The footwear industry is growing every year, generating a lot of waste. It is estimated that 23 billion pairs of shoes are made every year, out of which 22 billion are thrown into landfill.

While Western Europe and United States each consume 2 billion pairs of shoes every year, UK alone consumes more than 320 million pairs of shoes. For India, total footwear consumption is estimated to be 2.9 billion pairs by 2025. People generally need to replace their shoes every 8-12 months. As the consumption is increasing, so is the waste. In the US, every year people discard over 300 million pairs of shoes, of which 95% wind up in landfills. As per some estimates footwear production generates in excess of 100 000 tonnes of leather waste alone in a year. Let’s discuss the challenges associated with footwear waste and the various options to minimize it in detail.

Materials used in footwear making

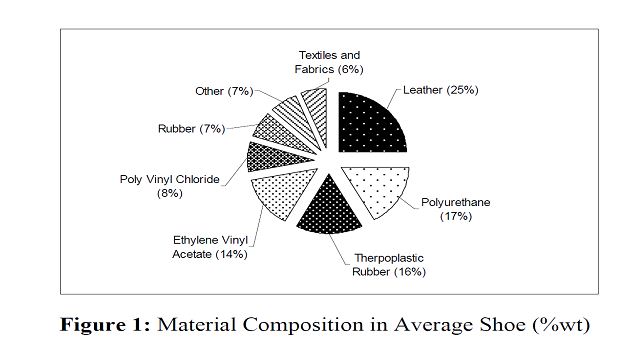

Around 40 different types of materials are used in shoe manufacturing. The materials usually used in shoe making are leather, textile and fabrics, rayon, nylon, cotton, polyester, jute, acrylic fiber and others (e.g. Polyethylene, Polyvinyl acetate, Polyvinyl chloride(PVC), Polyurethane(PU), Thermoplastic Rubber(TPR), Cellulose Rubber). These materials differ in their appearance, physical abilities, their service life, different treatment needs and also their recycling and recovery options at the end of their lifecycle. These materials take years to biodegrade. Natural materials take 20-80 years, leather shoes take 25-40 years, rubber shoes take 50-80 years and synthetic materials made from plastics may take up to 1000 years to decompose. Waste generated during leather processing is very high as only 20-25% of the raw material is used by the industry in the finished leather, and the rest 75-80% ends up in landfills. Some of the materials like leather, insole boards, thermoplastic polymers and textiles have the potential to be recycled, either within the footwear industry or within other industrial sectors such as packaging and construction.

Like any other industry, footwear industry also has its own challenges due to competition and needs of the customer like- being quick to market changes and staying updated to identify or establish new consumer trends. This leads to shorter product development cycle for the footwear industry, which leads to more shoe production over the years, which ultimately leads to more waste from the footwear industry.

Types of footwear waste

Different types of waste is generated during the entire lifecycle of a footwear, from manufacturing to its disposal. Some of them are discussed below:

Manufacturing waste

Manufacturing of shoes generates waste that includes scraps of materials like leather, rubber, fabric and foam.

Elastic and adhesive waste

Adhesives and elastic materials used during shoe manufacturing leaves residues that generates waste.

Packaging waste

Packaging waste is mostly generated from packaging materials that are used to ship and store shoes. This includes shoeboxes, plastic wrapping and labels.

Defective shoes

Shoes that are defective or torn out and cannot be sold are usually disposed of as waste.

Maintenance waste

These waste are generated during repair and maintenance of old shoes, like worn-out soles, old shoelaces and many other materials.

Post-consumer waste

Once a shoe has been used by a consumer for a certain period of time and is no longer needed or wearable as it is damaged, worn-out or out of fashion, it is usually disposed of or thrown away as waste.

Out of all these waste, post-consumer waste forms the highest percentage of waste generated from the footwear industry.

Impact of footwear waste on the environment

@ https://theshoeindustry.weebly.com/environmental-impact.html

Shoes that are dumped in landfills releases toxic chemicals into the soil and groundwater, thereby affecting the health of human beings and wildlife. Shoe factories mostly dispose their waste in ordinary dumps or release them into sewers. In this way dyes, adhesives and preserving chemicals are released into the environment. Dyes used in shoe making release harmful heavy metals, while soles decompose into chemicals like polyurethane.

Circularity in the footwear industry and its challenges

Although many footwear brands are coming up with circular footwear products and working towards circularity, implementing circularity in the footwear industry is little bit difficult and complex. The biggest challenge is most of the footwear nowadays are made in such a way that they are not detachable, making recycling of the materials more challenging. The complex blend of polymers that the footwears are made of are sewn and bonded together in such a way that it becomes difficult to recycle them. That’s why most of the footwear ends up in landfills. Consumer behavior and choice also play a role in adopting circular design. The most important thing that is needed is collaboration, not within the brands, but also multiple stakeholders like suppliers, infrastructure investors, government, academia and entrepreneurs in identifying solutions to increase the life cycle of a footwear. Footwear brands should work together in choosing sustainable materials for footwear manufacture and implementing programs for waste collection and recycling. They can co-invest in equipment and can combine extracted materials to make the recycling process more efficient. But most of the footwear brands are working individually in their efforts towards achieving circularity, which makes it harder to have any measurable impact. As most footwear companies nowadays are willing to adopt circularity in their business, proper planning is needed in the area of circularity and a common means of measuring progress, both of which are lacking.

Some of the footwear waste management techniques that can be practiced to achieve circularity are discussed below in detail.

Footwear waste management

The first step in minimizing footwear waste is changes in the manufacturing processes. To tackle the post consumer waste there are options like recycling, repairing, repurposing, donating, etc. that can promote circular economy in the footwear industry. Below are the details of various footwear waste management steps.

Manufacturing of shoes

Using sustainable or biodegradable materials for manufacturing of shoes reduces the environmental impact, when they are discarded after use. Sustainable materials that can be used for the production of shoes are cotton, hemp, linen, bamboo, wool, silk, natural latex, cork, castor oil, palm leaves and pineapple leaf fibers. The use of sustainable materials can be a bit expensive. But by doing thorough research one can get less expensive alternative materials. Also shoes should be manufactured in such a way that at the end of its lifecycle the recyclable materials can be easily recovered for recycling. Durability standards should be developed to ensure that the footwear can be used for a longer period of time. Collaboration is needed from different sources in order to make changes in the entire shoe manufacturing process.

Reduce and reuse

Consumers should buy high quality durable shoes as much as possible, that are long lasting , to reduce the amount of waste generated from frequent shoe disposable. For minor problems shoes can be repaired and refurbished so that it can be used again.

Recycle

When the shoes are torn out in such a way that it cannot be used again, recycling is the best option. Many footwear companies have recycling programs that recycle the shoe materials into different products like fillers for the surfacing of road, reinforcement in composites, sound insulation, playgrounds for kids, shock proof floors, electrical insulation, etc.

Donation

Shoes that the consumers have gently used and no longer wanted to wear them can be donated to charities and organizations that distribute them to the needy. Many NGO’s are actively working in collecting shoes and distributing them to the needy.

Education and awareness

Lack of awareness and education among the consumers about the harmful effects of footwear waste is the main problem due to which lots and lots of footwears are disposed off daily. Educating the consumers about what footwear waste can do to our environment and the various ways by which footwear waste can be managed, consumers can be encouraged to buy eco-friendly footwears, even though they are a bit expensive than the regular ones. It will also promote mindful consumption. As more and more millennials are becoming eco-conscious nowadays, they look for sustainability labels while buying shoes, verified by global or national agencies. So footwear companies adopting circularity can put such labels on the packaging or on the sole of the footwear in order to present itself as a sustainable brand, that will increase its purchase.

Steps by the government

Government can implement rules and regulations for the production of sustainable footwear and also waste management after use.

Research

Investments in research and innovation for the development of sustainable footwear materials, footwear production and management of waste is needed.

Initiatives to tackle footwear waste

To tackle waste from footwear industry many big footwear companies have come up with implementation of sustainable practices in their manufacturing and supply chain areas. For tackling post-consumer waste NGO’s are there that collect old worn out footwears and recycle or repurpose them for some other uses. Greensole, a Mumbai based start up recycle old and discarded shoes into new footwear and supply them to the children in need. Murtle, a Hyderabad based start-up upcycle old worn out footwears with new designs and make them wearable again. Many NGO’s are there worldwide that are doing their part in handling footwear waste. Soles4souls, an US based NGO is turning up old discarded shoes for good use. Another one is Satra Technology an UK based organization. Around 400kgs of waste footwear are collected from SATRA every month by local recycling companies. As nowadays most of the footwear contain materials and adhesives that cannot be recycled or reused, waste footwears are deconstructed by the recycling companies and turned them into refuse derived fuel (RDF). RDF technology produces energy from waste.

Conclusion

As the footwear industry, like the fashion industry, is growing day by day with fast changes in fashion and trends, it can adopt the principles of circular economy by way of implementing sustainable practices in the production and disposal of footwear which will reduce the impact on the environment. Collaboration amongst different brands and various stakeholders is needed to overcome the challenges in adopting circularity. Using sustainable and biodegradable materials for making shoes, investing in new technologies for the production and disposal of shoes, creating awareness amongst the consumers about the environmental impact of shoe waste and the importance of its proper disposal and also recycling, repurposing and reusing old shoes, the footwear industry can become a sustainable business and contribute its part in making a sustainable planet for all.